Email Us

sales@boltking.co.uk

Call Us

01952 350100

01952 350200

5 examples of typical work undertaken by Bolt King over the last 12 months.

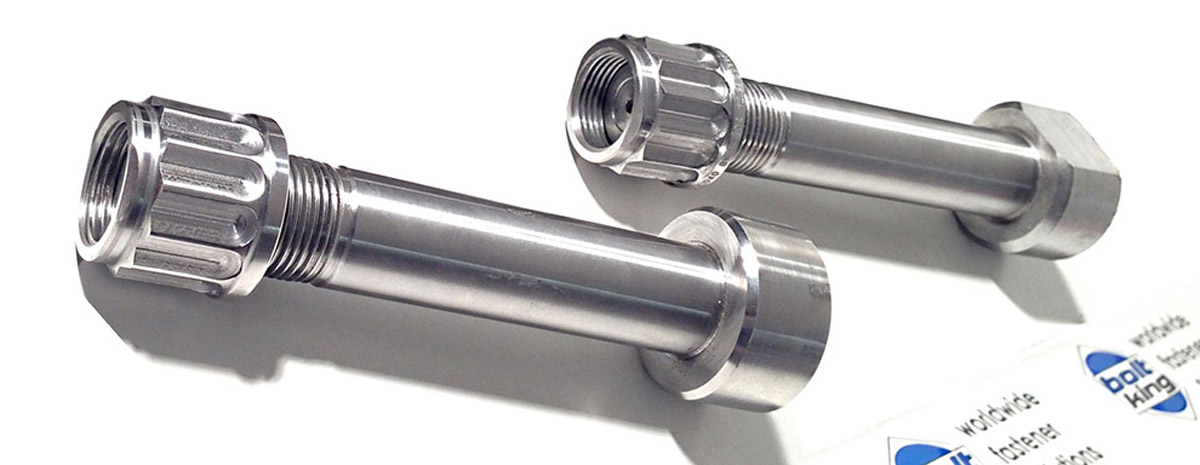

Dual Threaded Waisted Double End Stud, M64 (6.0), M68 (6.0), M70 (6.0) x 587mm lg Rolled Thread (Self Colour), c/w Tensioner Nut

| Customer : | Petrochemical Plant, Eastern Europe |

| Quantity : | 32 Sets |

| Material : | SA 540 B24 Cl.3 & Cl.5 |

| Manufacturing Method : | Precision Turned, Thread Rolled |

D-Head Bolt, 1-1/8" 12-UNF x 4.50" lg uhd (Self Colour), c/w 1 12 Point Nut

| Customer : | Offshore Gas Turbine Outage, North America |

| Quantity : | 48 Sets |

| Material : | INCONEL 718 (Cold Worked) |

| Manufacturing Method : | Hot Forged & Precision Turned |

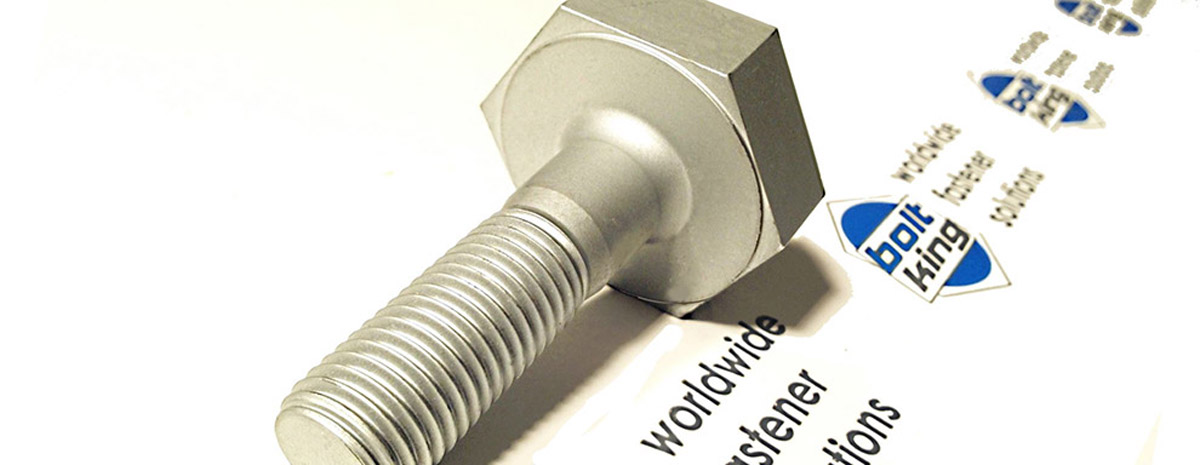

Super Heavy Hex Head Bolt, M20 (2.5) x 70mm lg

| Customer : | Defence Contractor, UK |

| Quantity : | 2000 pieces |

| Material : | BS970 817M40V 10.9, Geomet 500B |

| Manufacturing Method : | Hot Forged & Precision Turned |

Precision Milled Superconductor Connector

| Customer : | Nuclear Research Organization, Switzerland |

| Quantity : | 1800 pieces |

| Material : | INCONEL 718 |

| Manufacturing Method : | Precision Milled |

12 Point Nut, 3/8" UNF (3B)

| Customer : | Offshore Power Generation Group, UK |

| Quantity : | 400 pieces |

| Material : | Waspaloy (AMS 5709) |

| Manufacturing Method : | Hot Forged & Precision Turned |

Special Fasteners In Exotic Alloys, Including

Inconel & Super Duplex

Bolt King Ltd 2024 | All Rights Reserved | Privacy Policy | Built by